Vespa1960 VBA 150Hydraulic Clutch |

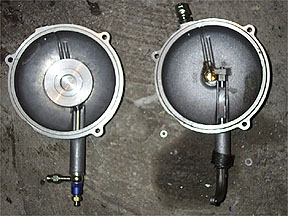

Hydraulic Clutch Conversion:This is probably the one thing that gave us the most amount of trouble... The kit is supplied from SIP with a modified clutch cover, some hydraulic fittings, the actuator, and a really fancy ball bearing pressure plate. Below is a picture of the original clutch cover and the SIP modified one. The workmanship from SIP is very good and the difference between the two is clear. The basic idea is that they have welded in a hydraulic plunger right where the original brass plunger used to be and then run all the hydraulics down to a banjo bolt and bleed valve.

On a normal engine the clutch rotates at all times and there is a pressure plate which covers the hole to the central nut, which is pushed to release the clutch. On the hydraulic one I think that SIP thought there would be a danger that the plunger might rotate when it was in contact with the spinning pressure plate.... So they came up with the ingenious new pressure plate shown below. This one has a small ball bearing plate in the middle which can move independently to the clutch which doesn't give the plunger a reason to spin. The one on the left is the original.

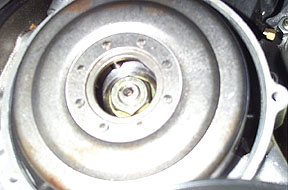

One thing I found very hard was to refit the retaining wire to the new pressure plate. The small access holes are much further apart than the original. With a bit of perseverance the wire will fit and retain the plate. Below is a new style clutch without the pressure plate fitted.

The only problem I had once the clutch system was bled was that once the cover was tightened down it slightly engaged the clutch even with the plunger flush with the plunger housing. The only way I could make the clutch work properly was to space the clutch cover out using very thin washers at the 3 fastening bolts. These were thin enough that the rubber oil seal didn't leak but it is still something I need to resolve with SIP.

Next Section --> |

||||||||||||||||||