|

|

|

|

|

|

|

||||||||||||

Vespa Small Frame Engine WorkGearbox Disassembly |

Gearbox DisassemblyOnce the cases are split you will have access to all the bearings and gearbox components to check and replace as necessary. This section will show how to remove the transmission from the cases. The Vespa Primavera engine in the shots below may be slightly different than your engine but most pictures will give you enough of an idea how to proceed.

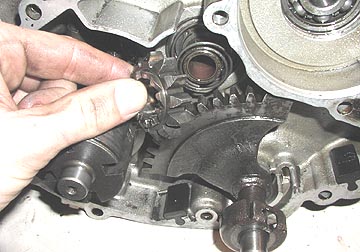

First we'll remove the kickstart from

the casings. This will allow you to replace the kickstart O-ring which

is a common place for oil leaks. It also will give better access to

remove the primary drive gear. The free gears have already been removed

in the images. Move the kickstart with your fingers until the small

kickstart gear can be removed.

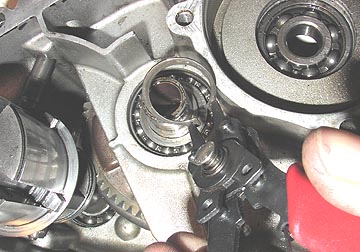

Once the kickstart gear is removed you

will see a spring which can also be removed. The kickstart spring was

previously removed so it is not shown in this picture.

The kickstart can then be pushed through

the casing and placed aside for the rebuild.

With the kickstart out of the way you

will see a small dished washer around the exit of the primary gear

shaft as well as a small circlip.

Remove the dished washer and note that

the dished part faces up and towards the flywheel side of the casings.

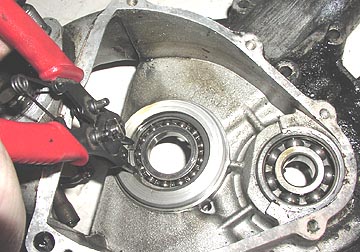

Using circlip pliers, remove the single

circlip that holds the primary gear shaft in the bearing.

Flip the casings over and carefully tap

out the main axle using a rubber faced mallet. If you don't have one,

you can just thread the axle nut on the axle so that it is flush with

the end and the treads are protected and use a normal finish hammer.

Carefully bang the axle out of the

bearing always watching the shift cross location. When the shift cross

is all the way down on the circlip you'll be able to disengage it from

the small selector "ears" of the selector assembly.

Then carefully bang the clutch basket

out from the central bearing.

It is a tight fit but it will come out

of the bearing and out the clutch side casing opening.

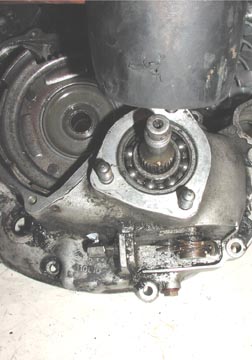

Above is a shot of the clutch basket

just clearing the bearing from the clutch side of the motor casing.

To remove the clutch bearing, use

circpli pliers to remove the single retaining clip. The bearing can now

be removed by banging it out from the other side. Use a large socket as

a block so that the rim of the socket is resting on the outer rim of

the bearing. Tha main crank bearing can also be removed in a similar

manner.

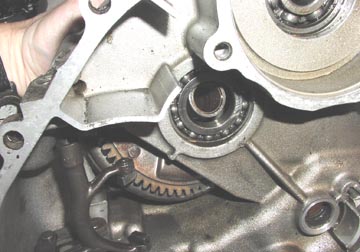

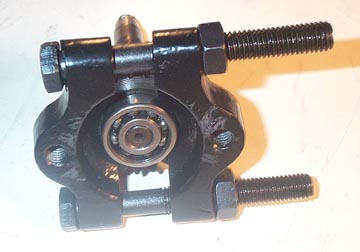

The gear cluster on the flywheel side of

the casing may be stuck in the bearing. Sometimes the bearing is tight

to the casing but sometimes they come out together. If this is the case

you can use a bearing splitter to force it off the shaft.

The bearing can now be cleaned and

reused if it feels good, or replaced.

Next Section - - > |

|||||||||||||||||