|

|

|

|

|

|

|

||||||||||||

Vespa Post 1979 Large Frame Engine WorkBearings Clutch Rebuilding |

Clutch RebuildUsually when the clutch is not functioning well, nine times out of ten the plates need to be replaced. These images are from a P200 clutch but large frame clutches are similar but may have different amounts of springs. Once the clutch has been removed changing the plates and any other work is easy. You'll need:

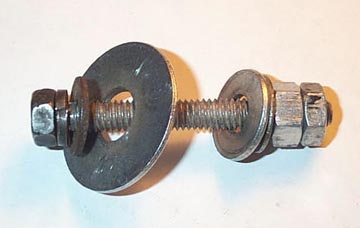

A special Vespa clutch compressor is a nice tool, but you can make one for under $4 at your local hardware store from standard nuts, bolts and washers. You are looking for:

Above is a view of a compressor I made

from parts in the garage. Take the clutch with you to the hardware

store to be sure of getting the right bits.

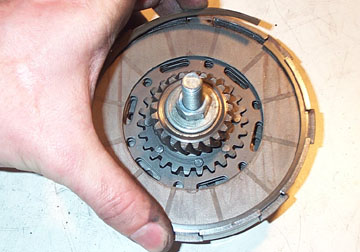

Put the clutch compressor through the

central crank hole. Make sure the washer on the side with the spring

holes is totally covering the central hole, and then tighten up the

compressor. You only need to tighten it enough so that the pressure on

the circular perimeter retaining ring is released. Remove the ring by

pulling it out of the groove.

Once the ring is removed, the first one

sided cork plate can be removed. This plate differs from all the other

plates because it has different shaped tabs and must be the last plate

installed. These tabs lock the cork plates to the outer basket. The

next plate is a full steel plate which is teethed around the interior

perimeter to lock it to the clutch center. Remove all the free

alternating steel and cork clutch plates.

The final steel clutch plate is riveted

to the clutch center gear. The clutch compressor needs to be removed in

order to remove the center gear from the basket and to get access to

the springs. Once the compressor is removed I usually get a large

socket to set the clutch on so that the spring cups are not touching

the work surface.

The clutch center gear and plate should

be easily removable from the main clutch body. In the clutch above the

brass bush came off with the center plate instead of remaining on the

body, but I'll describe what should go where in the next couple of

steps.

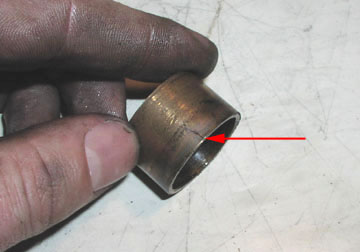

Remove the small brass bushing. These

are very cheap and easy to get through a scooter dealer and should

always be replaced when doing clutch work.

Remove the main clutch body and the

springs and spring cups will be visible. You can see the large socket

in the center supporting the clutch basket. This makes it easy to deal

with the spring caps because they will be held in place by gravity. If

you bought new springs remove the old ones and place the new ones in

the cups.

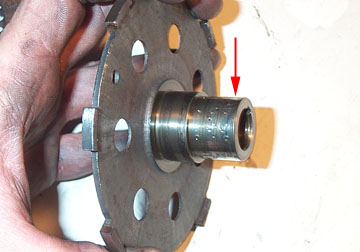

Inspect the clutch main body for wear.

The interior components of the clutch don't run on bearings, but run on

brass bushes at the friction points. This clutch had a cracked brass

bushing which allowed the bushing to slightly expand in size and lock

to the clutch center gear instead. I'm not sure how the damage above

happened on the surface of where the bushing should be, but this entire

part should be replaced and a new brass bushing will be added to the

new piece.

The cracked bushing can be driven out of

the clutch center gear by using a suitable sized socket and hammer to

pound it out from the back side. In order not to bend the steel plate,

don't support the piece by the plate while pounding the bushing.

Usually they are a loose fit and just holding the center in your hand

is enough support to bang it out.

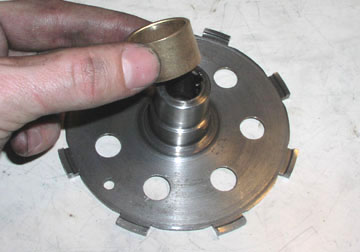

Fit a new brash bushing to the main

clutch body. This should be a nice tight fit so the bushing does not

turn. Use a large socket or flat piece of metal to tap it until the

lips are flush.

Then fit the second brass bush ring with

the small lip facing upwards. This is a very loose fit and can rotate

freely.

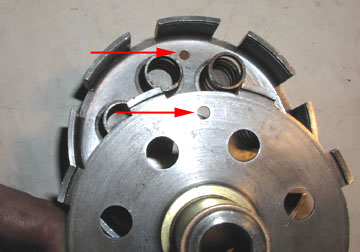

Place the main clutch center over the

springs so that they seat in the recesses on the back side. I have

always aligned the two holes shown above with arrows but I don't know

if it really makes a difference.

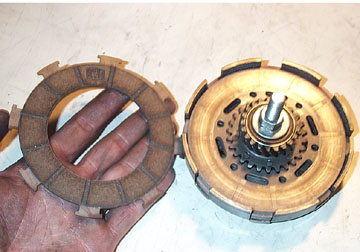

Fit the main clutch center and spin it

to be sure it rotates well. Above is a shot of the clutch plates in

their correct order from left to right.

Fit the first cork plate and make sure

the tabs are closely aligned with the tabs of the main clutch as it

will make them easier to drop down in the basket when the clutch is

compressed.

Fit a steel plate which interfaces with

clutch center teeth. Keep alternating cork and steel plates until you

get to the final one side cork plate.

Once all the plates are in and the final

one side cork plate fitted, compress the clutch and help all the cork

plate steel tabs drop down in the clutch basket.

Finally, fit the retaining ring in the

groove in the clutch basket and your clutch is ready to reinstall. |

|||||||||||||||||