|

|

|

|

|

|

|

||||||||||||

Vespa Small Frame Engine WorkInstalling a piston |

Installing a new pistonThe piston and barrel need to be in perfect shape to get the most out of your motor. Typically the difference in diameter between the two is only 0.2mm and if any metal shavings or other material get in between them you will get scoring which leads to a new piston and rebored barrel. You will need:

The Vespa 100 Sport engine shown here is a little different than most small frame bikes. It has two transfers in the casing mouth, but also has a third in the barrel itself like a Vespa ET3. The barrel bolts are short studs and the head attaches to the barrel rather than long studs holding the two together. With a little revision for your motor this should help you get a new piston and new rebored barrel back in the bike.

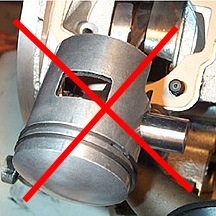

The piston on the left is the brand new oversize piston compared to the badly scored original. When scoring like this happens it is required that you get a rebore at the same time as a new piston. Your local scooter shop will be able to measure the barrel and rebore to match the new rebore diameter with a new oversize piston.

Pistons typically come with new rings that are sized appropriately, two new circlips for the gudgeon (wrist) pin, and the gudgeon pin. On a standard piston, the rings have ends to them that are cut so that only one way will fit. Have a look at the ring grooves in the piston. At a single point on each one there will be a ring stop pin set in the groove which it typically on the upper edge of the groove. The piston ring needs to be installed so this pin fits nicely in the offset circular portion of ring.

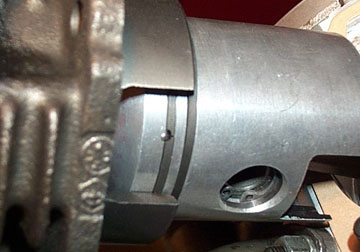

To get the ring on the piston, carefully stretch it over the outside diameter of the piston. Once stretched around the circumference, carefully slide it down the sides until it locates in a groove. Both rings are the same so it doesn't matter which one goes on first or in which groove they go. Once they are in the groove they will be loose and can spin. Before the barrel installation they will have to be centered on the piston ring pin.

Above is a shot showing the lower piston ring installed correctly with the ends correctly located near the piston groove pin.

Place the paper gasket over the crankcase mouth. Because the bolt pattern is square this gasket can be placed upside down. I was surprised to find it didn't fit perfectly, but as long as the transfers are not covered then it is installed correctly.

Inspect the small end caged needled bearing for any wear. Fit the new gudgeon pin into the bearing and then place the whole bearing/pin assembly in the small end to test for a good fit. If there is no perceptible play and things feel solid then rub some two stroke oil over the bearing and fit it ready for the piston.

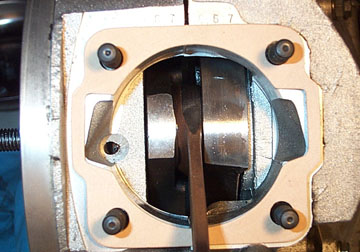

The piston can be installed two ways, but only one way will allow the engine operate properly. One a three port motor like the Vespa 100 Sport there is a window in the piston opposite the exhaust port in the barrel. Unlike a large frame motor, a Vespa small frame barrel has the exhaust coming out of the high side of the barrel. The piston is marked with "SC" and an arrow for clarity. This arrow needs to face the exhaust port. The picture above shows the correct location of the third port window if you are looking at the motor from above. If you do not have a third port type piston, make sure the "SC" faces the exhaust port.

Push the gudgeon pin in from either side so that it passes through the small end. Sometimes these pin are tough, so you can warm the piston with a hot rag or freeze the pin if it is too hard to move by hand. The different material temperatures will give you a little more play. Use circlips piers to fit the circlips on either end of the pin. Make sure they fully sit in their grooves because you don't want them coming loose once the engine is running.

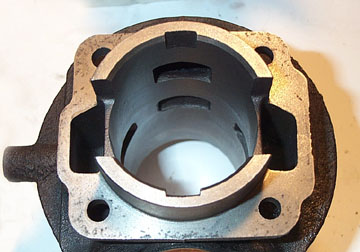

Above is the old barrel which has been rebored and honed to get a nice smooth surface on the bore. The exhaust port is located just off the photo at the bottom, and the 2 main ports and third barrel port are clearly visible. Use some two stroke oil to smear around the inside of the bore - this makes the piston slide in a little easier and gives a coat of oil to the bore for the initial start up.

Take the barrel and slide it down over the first part of the piston until it hits the first ring. You will need to compress the ring with your fingers, making sure the piston ring end is aligned with the groove pin as shown above. The spigot (the bottom part of the barrel that sticks out) is slightly bevelled to help the rings seat properly. Once the ring is compressed you can start to slide the barrel down over the piston. If the piston sticks the rings may not be seated properly and you should remove the barrel and try again.

With the piston in place turn the flywheel and make sure the piston moves smoothly through the bore. You barrel might have the studs protruding through the barrel where the one shown only has threaded holes. This is due to the weird 100 Sport stud and barrel discussed earlier. If everything turns smoothly you can reattach the head (reverse of this page) and move on to installing the cylinder shrowd and getting back on the road. |

|||||||||||||||||