Vespa Pre 1979 Large Frame

Engine Work

|

|

Oil Mixer (Autolube)

The Vespa 150 Super was the first Vespa

to have a separate two stroke oil tank with a mixer device to correctly

mix oil and gasoline in the engine intake. For the first time Vespa

owners could put in a quart of oil through one filler cap, and then

fill up with typical gasoline in the main tank, with no fussy mixing at

the station. There were two systems used over the run of the Vespa

engine. The first system is noted in this section and was used on any

bike with autolube up to the P series models.

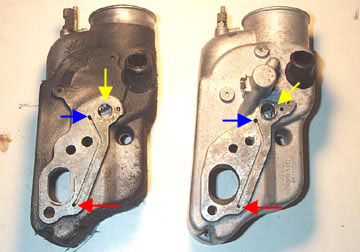

The system is driven off a small gear on

the crank which powers a small oil pump by a worm drive. The pump is

located in the carb box just forward of where the carb should be. The

carb boxes above are of the two different systems. On the left is the

older system used up to the Rally 200. On the right is the P series

system still in use today. Both systems have an arm which connects to

the throttle linkage so the amount of oil pumped is in relation to the

engine speed from the drive and the throttle position.

Above is a shot of the underside of the

carb boxes for both systems. Again, the older system is on the left and

the newer system is on the right. Both use the idea of a pump with a

small groove in the bottom of the carb box to get the oil feed from the

pump to the carb. The drive hole from the worm gear is marked with a

yellow arrow, the oil pumped from the pump comes out of the hole marked

with a blue arrow, and then moves down the groove to the red hole where

it enters the carb.

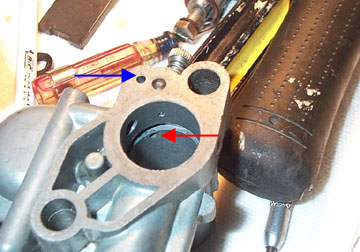

Once it comes through the carb box it

goes into the carb where the blue arrow is shown, and is combined with

the gasoline when it comes out of the hole marked with a red arrow,

above the throttle slide.

There is really not much to service in

the pump other than replacing the gasket and making sure the pathways

are clear. To service the oil pump in the older system, remove the

three flathead screws that hold the pump body to the carb box. Once

these are removed you can carefully twist the pump out of the box.....

...and slide the oil intake line through

the carb box body. Discard the old gasket as it should be replaced

whenever the pump is removed.

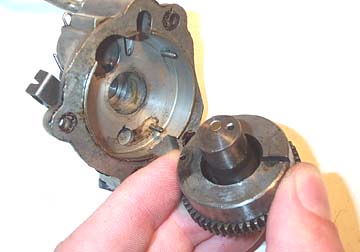

Once the pump body is out of the box,

have a careful look at it to see how it works. It is a little

complicated, but once you understand it, it starts to make more sense.

The central drive gear can be removed by

pulling it out from the pump body. Pay particular attention to how the

throttle arm linkage connects to the circular piece above the gear, and

how the slot in the gear aligns with the small dowel in the pump body.

The circular piece can also be removed from the drive gear to

expose another circular piece which slides on a dowel to the main drive

gear.

...and finally a small bushing between the two. I took this

apart to see how it worked more than anything (I'm like that). For

servicing make sure all the parts are clean, and the passageways in the

carb box are also clean.

When you replace the pump back in the carb body always use a

new gasket between them.

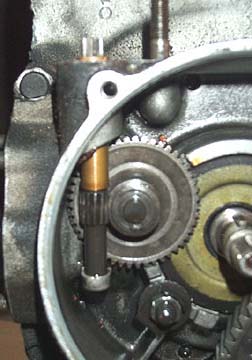

The drive itself is the only other part that needs to be

checked. It is turned by a small gear that is on the end of the crank

between the clutch and the oil seal. It is held on the shaft by the

woodruff key in the crank end. In the picture above it has been

removed. A second drive gear turns on a small shaft embedded in the

casing, which ultimately tuns a vertical shaft via a worm gear. Check

that all the teeth in all the gears are in good condition. Spin the

gears to make sure the oil drive vertical shaft turns. It will turn

very slowly.

If the shaft needs to be replaced it can simply be lifted out

of the casing. Once the oil pump is back together you can test it by

this simple test. First, connect the oil line from your bike to the

carb box oil intake. Then, take the vertical shaft drive out of the

casings and very carefully and loosely chuck it up in a variable speed

drill. Insert the end of it into the underside of the carb and slowly

rotate it in the counter clockwise direction. On the underside of the

carb, oil should start to dribble out of the hole next to the drive

hole (in the groove).

When you install the carb box, use a new gasket between the

casing and the box. There are a bunch of different gaskets out there so

make sure you have one that has a hole for the mixer drive gear.

Make sure the gear engages into the oil pump hole when you

place the box down on the casing.

Finally, make sure the gasket you use between the carb has the

hole punched out as shown above. If not the oil will make it all the

way from the pump to the underside of the carb box and then hit a dead

end. The hole in the gasket must align with the oil hole in the carb

box for the oil to make its way into the engine.

|

|

|