|

ScootRS Lambretta Disk Brakes Installation

- Part 1

I bought this disk kit from ScootRS about a year ago and never

had the time to install it. I was also less than motivated since the

TS1 it was going in was still not complete.

The kit came with the following:

- The hub, axle, disk, and caliper as a

single assembled unit. It even had rim nuts & washers.

- A master cylinder with brake switch

which was bolted to a TV style handlebar switch block (LI style also

available)

- New fork links with damper

attachments.

- Two new dampers with weld on top

clips.

- A rubber hydraulic line with all the

fittings at either end.

The only thing the kit didn't include

for a full installation was hydraulic fluid, bolts for the top damper

connections (easily found locally) and instructions (ScootRS recently

let me know that these are contained in the original purchase email).

The first step to the kit if you have non-damper style original forks

is to drop the forks

from the frame and remove the front wheel. The clips must be welded

in place and there is the possibility of damaging the suspension system

if the forks are not stripped. If you already have disk fork links you

can skip ahead to the hub installation.

The forks on the LI125 Special are the

same as GP 125/150 forks so the rubber stop blocks are a little

different than the standard LI. A fork compressor is handy for the job

but not needed. The first step is to use two sockets or a wrench and a

socket to remove the single large pivot bolt at the front of both legs

of the fork. Make sure you note which fork the cable guide is attached

to if yours is the bolt on type.

Once the nut is loose the bolt can be

pushed or tapped out from the other side.

With GP forks I was able to push the

fork link back far enough to remove the rubber bottom stop even without

the fork compressor tool (even though it is shown here). The rubber

fork stop is held in place by a metal lip on either end. To remove it,

push in the lip and it should come free. Have a look at the later

pictures of the bare fork to get an idea of what the lip looks like

with the rubber stop removed.

With the bottom stop out of the way

there should be enough slack between the spring and the link that you

can pull the link free of the forks. Be sure not to lose the metal ball

which sits in a cupped area in the center of the fork.

The washers on either side of the link

can simply be pulled off if they are stuck in place.

With the fork link out of the way, the

typically nasty single spring can be removed by pulling on the end

pieces. A central metal rod will also come out with it. Clean these and

place them to one side for the install.

Above is a shot of the metal rod and

cup. Make sure it is not bent and check for major wear at the ball cup

end.

Once the spring is removed you'll be

able to see the other fork link bump stop. It comes out in the same way

as the lower one, by clipping in to a metal retainer. Or you can leave

it in if you don't plan on replacing it.

Now that the forks are bare you can mark

them for welding on the upper brackets for the new fork dampers. The

job of the damper is to stop the bouncing motion of the front of the

bike when it goes over a bump. They are highly recommended especially

for a disk set up. The clips supplied with the kit should be welded on

at 9 1/2" from the curve cut out at the bottom of the forks as shown

above. The bend in the clip will fit the tube diameter of the forks.

I found a can of spray paint that

matched the original Lambretta color pretty well. Once the welding was

complete I cleaned them up, gave a quick spray of primer over the bare

metal area, and then sprayed the clips. It is OK from far away but you

can tell when you are close up. Obviously if you have a nice paint job

you'd have to get the forks redone properly.

Grease up the fork spring and central

rod, and fit the upper fork stop rubber if you plan to replace them.

Slide the spring all the way in and the rod should slide up as well. It

may need a little wiggling to get it to slide up.

Now the new disk ling goes in with the

dished washers on each side facing in. Make sure the disk link offset

faces in towards where the wheel will be.

Grease up the small ball which goes in

between the bottom of the fork rod and the little recessed area in the

disk link.

Push the single large bolt through the

front of the forks. If you have the type of forks with a separate cable

holder don't forget to install it followed by the shake proof washer

and finally the nut. Don't tighten it more than finger tight for now.

Compress the fork spring enough to get the lower bump stop in to the

clip. There are a couple different methods to do this and the fork

compressor tool is the best option, but it can also be done with the

forks in a vice and a friend pulling back hard on the link. Make sure

it is a good friend - if they let go you'll get your fingers squashed.

Once the bottom fork stop is in, tighten the front pivot bolts with a

socket and wrench. The forks should now be put back in the frame.

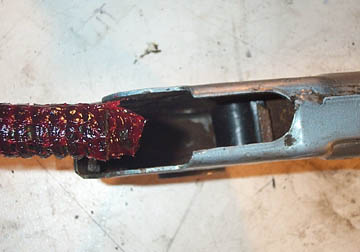

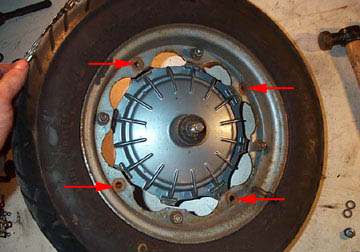

Remove the old brake shoe hub from the wheel rim by loosening

the four 14mm nuts around the perimeter. Make sure you only undo every

other nut as the other four nuts keep the wheel rims together.

Get the entire new hub and fit the wheel rim to it. Make sure

that if you have directional tires, the arrow faces in the direction of

forward rotation. The disk caliper should face out towards the right of

the bike. Take the wheel and hub unit and find the large slot in the

plate that hold the caliper on. This slot goes on to a peg on the right

hand side fork link and stops it from rotating with the wheel.

With the disk plate in the disk link slot, move the wheel axle

up into the axle slot and fit the thick washers which drop into the

recess in the end of the link. These are very critical to keeping your

front wheel on. I recommend getting brand new ones to be safe.

Above is a shot of the hub in place with the washer in the

correct location, ready for the axle nut. Put an axle nut on each side

of the axle and tighten them down fully. Make sure the wheel rotates

smoothly and doesn't have any wobble to it.

Fit the damper to the fork link with the supplied hardware as

shown above. I did find that my dampers rattled a little but this was

fixed by screwing the upper mount tighter on the casing.

The final step in the lower end of the

hardware is to attach the top end of the damper on each side. Since

this hardware was not included I used a 6mm Allen head bolt with a

nylock nut on the inside.

|

|