|

|

|

|

|

|

|

||||||||||||

Vespa Pre 1979 Large Frame Engine WorkBearings - Crank Bearings |

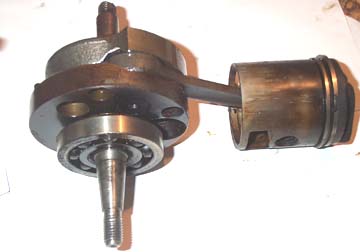

Main (Crank) BearingsOlder large frame Vespas use the same

bearings on either side of the crankshaft. Once the cases are split and

the crank and oil seal have been removed you can replace these

bearings. The bearings are part number 900100 and their size is

25x62x12.

Above is a shot of the main crank

bearing left in the dutch side of the casing. It definitely needs to be

replaced, the casings need to be cleaned, and then a new bearing needs

to be installed. Typically the flywheel side bearing will remain on the

crank and the clutch side bearing will remain in the casing.

Once the oil seal has been removed, use a

socket or something similar to drive the bearing from the clutch side

by hitting it with a hammer.

The above is a shot shows the bearing

being driven through the casing and getting close to coming out.

Clean the casings once all the bearings are removed if yours

looks anything like what I started with. You can also install the oil

seal from this side (see oil seal

installation page) or just do it from the other side after the

bearing is in place. Heat the casings beforehand to make the aluminum

expand a little. There is no front or back side difference to the

bearing so it can go in either way.

A useful tip is to use the original bearing that was removed

as a drift to install the new one. Carefully tap down the new bearing

so that it seats squarely in the hole.

The other main bearing is typically left on the crank after

the casings are split. To remove this you either need to buy a special

tool, or just take it to your local scooter shop to have them pop it

off for you.

You can also use a basic bearing puller

to do the job if you don't want to spend the $60+ for the special

Piaggio type tool.

With the bearing off you can see the

area where the new bearing will sit (red arrow), and also the shoulder

(blue arrow) which stops the bearing from going all the way to the

crank web. This shoulder makes sure there is a gap between the bearing

and the crank for future bearing removal. To install the new bearing

you can freeze the crank and warm the bearing to make things easier.

When installing the new bearing make sure you support the flywheel side

crank web only. An easy way to do this is to slide a thick piece of

steel between the two webs and support it on either side. This is

imperative as you can bend the crank if the web is not fully supported

and you start banging away.

Use a large deep socket or a section of metal pipe to bang the bearing down on the shaft. The socket or metal pipe should only rest on the interior race of the bearing so it doesn't cause damage to the bearing. |

|||||||||||||||||