|

|

|

|

|

|

|

||||||||||

Gearing |

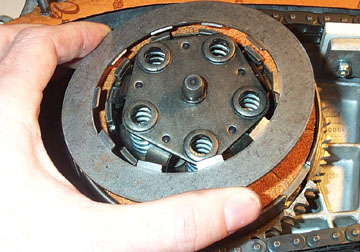

Lambretta Five Plate ClutchThe typical Lambretta clutch has four cork plates and five springs. As the power of the tuned cylinder and cylinder kits increases these clutches tend to slip rather than transferring the power to the road. You can add very stiff springs which can correct the problem, but also makes the clutch harder to pull. Another alternative is to convert to a 5 plate clutch to get 25% more area for the clutch to grip. This page shows the installation of a five plate clutch from Taffspeed on a TS1 motor. The page starts assuming you have opened the chain case, removed the existing clutch and then either machined the existing bell or replaced the bell with one previously machined by a scooter shop. You'll need:

The idea behind the five plate clutch

conversion is to modify the clutch bell housing to allow the plates to

sit deeper in the housing and allow more plates to be used. The image

on the left is a standard clutch bell housing and the one on the right

is modified to let the tab of the cork plate sit lower than the

perimeter of the housing. You will only need to remove enough metal to

allow the cork plate past the lip. More than this can possibly weaken

the outer clutch teeth.

Your existing clutch plates also need to

be replaced with new plates which are thinner than the 4 plate ones as

shown above on the left. The new thinner clutch plates also come with

new steel plates as you'll need one more compared to a four plate

standard clutch.

The clutch bell needs to be either

removed, machined and replaced or a new one should be installed with

the machining previously done. The central clutch basket remains as

standard (this is a GP200 clutch shown).

As part of this conversion I also

purchased new stiffer springs from Taffspeed. These springs are

marginally stiffer than standard so that using the clutch will be close

to the standard resistance. The springs are installed just like a

normal clutch rebuild.

Fit the original upper clutch plate and

make sure the springs locate in their top holes. Since the clutch is

not yet compressed most of the plates in the following steps will not

engage the clutch outer bell or inner clutch tabs. These can be aligned

when the clutch is compressed later, but the order in which they are

placed is important.

After soaking the new thinner cork

plates in 30W oil, start by fitting a cork plate first. The tabs around

the perimeter should be orientated to drop in the slots in the clutch

bell when the clutch is compressed. After the first cork plate...

...install the only steel plate that has

bent tabs. Make sure the tabs are bent facing away from the crankcase.

Above is a detail shot of the tabs

facing up on the the first steel plate. These must be facing up so that

this plate connects more reliably with the clutch center. Continue

alternating plates until all the flat steel and cork plates are

installed. Make sure all the steel plates are flat. The steel plate

internal tabs must align with the tabs in the clutch center.

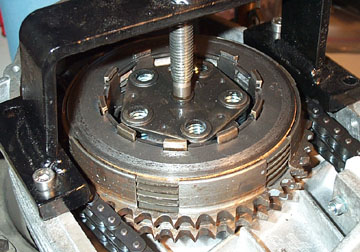

Once all the plates have been placed,

place the original thicker bevelled clutch from your original clutch.

Using a clutch compressor compress the center of the clutch

fully. The plates will probably remain out of their grooves until they

are helped down.

Once the clutch is compressed you can

start to help the plates drop down fully into the clutch body.

Once all the plates have dropped down

the retaining clip groove in the clutch center should be visible above

the thick bevelled top steel clutch plate. If this groove is not

clearly above the top plate then there is something not correctly

fitted (maybe a spring or plate) and you will need to double check

everything to make sure it is clear.

Fit the retaining ring in the groove.

Some people like to center the ends of this ring in a clutch center

tab, and some swear by leaving the ends exposed - I haven't found a

benefit either way so it is up to you.

Decompress the clutch but don't remove

the compressor yet. Have a close look at where the final cork plate tab

slides into the clutch bell and make sure that it is solidly in the

clutch groove. The image on the left above shows the tab on the

decompressed clutch not fully in the groove. If an engine was run like

this I assume the final clutch plate would be allowed to rotate freely

with the clutch center instead of being locked into the clutch basket.

I called Taffspeed about this and they sell final bevelled plates in

various thicknesses from 1mm to 3mm. Some clutches are fine with the

standard thickness and others need a thicker one. I measured the amount

that the tab was sticking clear of the basket and ordered a 3mm thick

plate to compensate. The image to the right is with the new thicker

bevelled plate installed and it clearly pushes the final cork plate tab

down into the clutch bell slot.

Remove the clutch compressor and make sure that everything is straight and that the retaining clip is firmly in the groove. Refit the chain case with a new gasket, fill it up with oil, and take it for a test drive. Next Section --> |

|||||||||||||||